- Home

- Audio

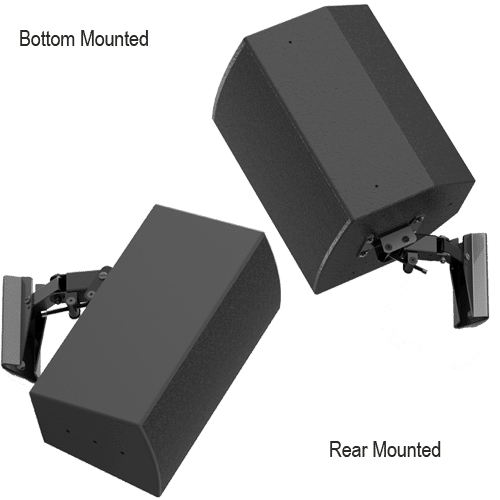

Audio Mounting

Audio Mounting

Audio Rigging

Audio Rigging

- ▼ Single Loudspeaker Rigging

- • One-Way-Array Single Speaker Rigging

- • Swivel Beams – Speaker & Line Array Rigging

- • Swivel Beam Clamps – Steel Beam Rigging

- • SwivelBeam Clamps – Wood Beam Rigging

- • Single Pulley Speaker Tilt Cable Kits

- • Double Pulley Speaker Tilt Cable Kits

- ▼ Planar Array Clusters

- • FASPAC™ – Speaker Cluster Rigging

- • BumperWare – Speaker Arrays & Cluster Rigging

- ▼ Line Array Rigging

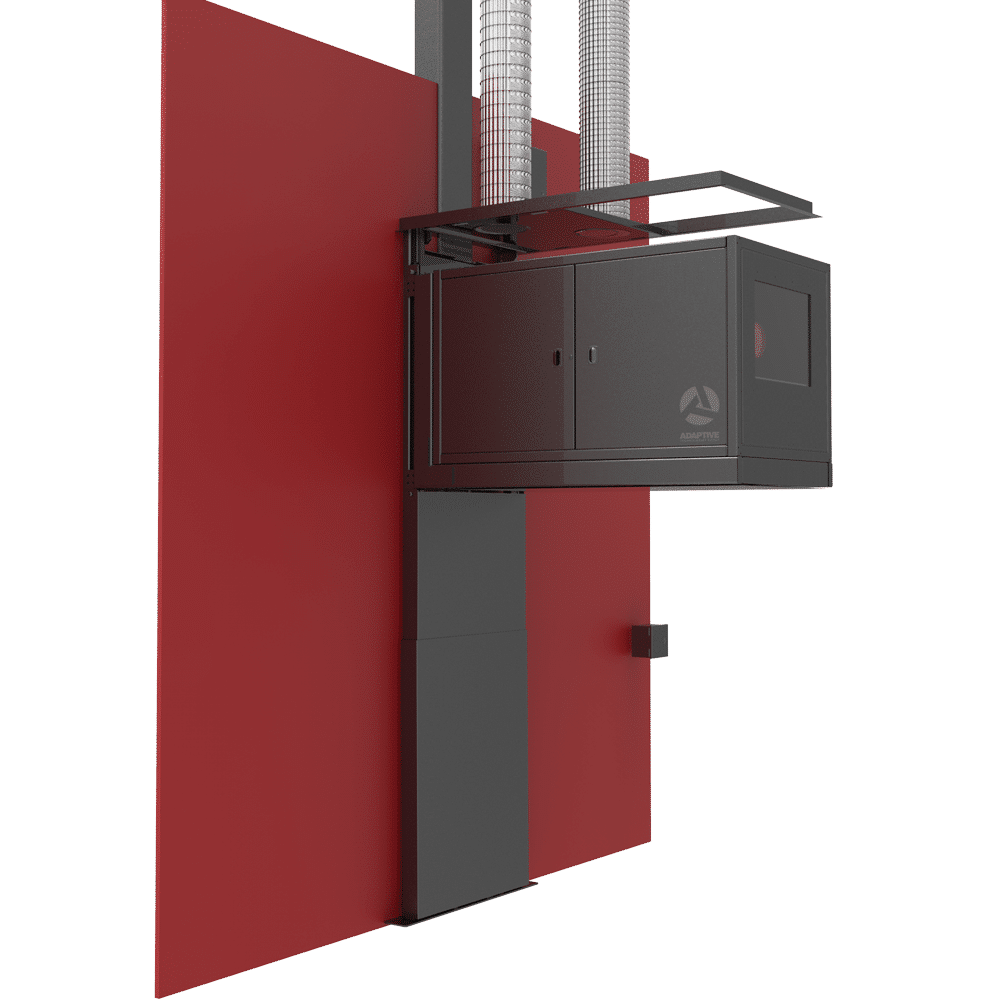

- • Line Array Wall Mounts

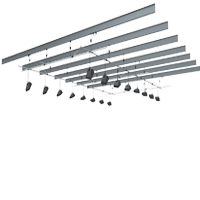

- • Overhead Grids

- • Grid Extensions

- • Sub Arrays

- ▼ Spherical Speaker Arrays & Cluster Rigging

- • Two-Way-Array – Speaker Cluster Rigging

- • Gridlink – Spherical Arrays & Cluster Rigging

Model Specific

Model Specific

- Video

- Cinema

- Downloads

- Overhead Hardware

- Sales & Distribution

- Even More